New possibility promoted by a new material!

We are widely trusted by our advanced technology.

| Clause. | Testing method. | Testing condition. | Unit. | Flame retardant non-halogen. | Flame retardant non-halogen. | Flame retardant non-halogen. | |

| Strength resin. | Conductive resin. | Slidable resin. | High strength resin. | ||||

| FL202A | FL205A | FL208 | FL501A | ||||

| Tensile strength. | ISO 527 | MPa | 120 | 130 | 57 | 155 | |

| Bending strength. | ISO 178 | MPa | 180 | 180 | 89 | 235 | |

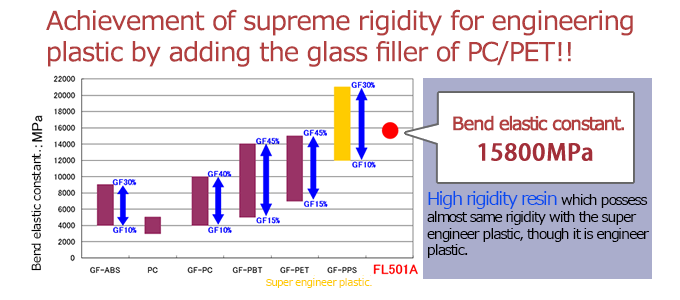

| Bend elastic constant. | ISO 178 | MPa | 8300 | 14000 | 3100 | 15800 | |

| Charpy impact value. (with notch). |

ISO 179/1eA | 23℃ | kJ/m2 | 10 | 6 | 9 | 11 |

| Load deflecting temperature. | ISO 75 | 1.80MPa | ℃ | 101 | 125 | 83 | 98 |

| ASTM D648 | 1.82MPa,6.4 | 106 | 130 | 83 | 110 (IS0 75/0.45MPa) |

||

| Combustibility | UL 94 | V-1/1.5mm | V-0/1.6mm | V-0/1.0mm | V-0/1.5mm | ||

| V-1/0.75mm | |||||||

| Volume resistivity. | D257 | Ω-cm | - | Less than 10³ |

- | - | |

| Mold shrinkage factor. | ASTM D955 | % | 0.1~0.3 | 0.1~0.4 | 0.4~0.6 | 0~0.22 | |

| Coefficient of linear expansion. | ISO 11359 | 20~80℃ | ×10-4(1/℃) | 0.639 (TD) 0.418 (MD) |

- | 0.699 (TD) 0.652 (MD) |

0.403 (TD) 0.296 (MD) |

| Density. | ISO 1183 | g/cm3 | 1.43 | 1.39 | 1.21 | 1.68 |

Note: These numerical values are the representatives, not the guarantee of its quality.

Grade of high rigidity.

FL501A

~Material characteristic which is advantageous for the high rigidity.

~

The cost will be reduced by alternation from metal shaft to the resin shaft!!

By the replacement of metal to resin, approximately 35g will be reduced if the shaft is φ6×200.

Contribution for saving energy!!

Because it is hard to be bent, so it is possible to improve the conveyance power by making the shaft more thin.

Material which was manufactured for pursing the low rate of warpage. Realization of stable and low warpage.

<< Comparison of the data about the radical run-out which was molded by φ8×500. >>

| FL501A | PC+ABS | |||||||||

| Average. | 0.191 | 0.284 | ||||||||

Note: These numerical values are the representatives, not the guarantee of its quality.

The deflection can be corrected in about 30% from the previous condition.

Because of the low rate of CTE (Coefficient of Thermal Expansion), the stable dimensions under the high temperature was achieved.

| FL501A | PC+ABS GF | ||||||||||||

| Coefficient of linear expansion. (1/K) |

Flow direction. | 2.96×10-5 | 4.18×10-5 | ||||||||||

| Vertical direction. | 4.03×10-5 | 6.39×10-5 | |||||||||||

Note: These numerical values are the representatives, not the guarantee of its quality.

Acquisition of the electrical property which is almost same with the thermosetting property.

| FL501A | Diallylphthalete. | ||||||||||||

| Strength of breakdown. (kV/mm) | 34.4 | 15.7 | |||||||||||

| Relative permittivity. (ε') | 4.08 | 4.5 | |||||||||||

| Arc-resistance. (sec) | 124 | 150 | |||||||||||

Note: These numerical values are the representatives, not the guarantee of its quality.

Advantageous for chemical resistance!

Grade of slide.

FL208

~Sliding material having excellent sliding characteristic.

~

Excellent sliding! Realization of the low coefficient of friction which is overwhelming superiority to the flat smoothness!

- ◯Less self-abrasion and suppress the abrasion of opposite material!

- ◯Availability of shaftless and sleeveless!

- ◯No inclusion of glass fiber!

- ◯Availability of recycling!

- ◯We are using the non-halogen flame retardant which is tolerance for natural environment.

Friction and wear property.

Abrasion test based on the Suzuki’s official system.

- ・Contact pressure. :1kg/cm2

- ・Circumferential speed. :10cm/sec

- ・Running distance. :1km

- ・Position of the opposite material. :Upper POM.

| Ratio of abrasion. (mm3/kg・km) |

|||||||

| FL208 | PC+ABS | ||||||

| 0.05 | 0.29 | ||||||

Note: These numerical values are the representatives, not the guarantee of its quality.

Grade of conductivity.

FL205A

~Superior characteristic of the conductive material.

~

Less than 103 for volume resistivity was achieved!

- ◯Bend elastic constant is 14,000 MPa!

- ◯Volume resistivity is less than 103Ω-cm!

Grade of low cost.

FL202A

~Strong material characteristic which is advantageous for the versatilities. ~

All the requirements were achieved by promoting the excellent formability and dimensional stability!!

- ◯We are supplying the precion molded products by taking advantages of low shrinking percentage and high mobility!

- ◯We are using the non-halogen flame retardant which is tolerance for natural environment.